Learn how to set up and adjust your laser sensor on the Anajet mPower Garment Printer

customer

2.7 Obstruction Laser Sensor Adjustment

Tools Needed

o Phillips Screwdriver

o Laser Gauge

The laser sensor can only be adjusted once the Table Z-axis motor limit flag has been adjusted see section 2.6 Before adjusting the laser you will need to have your printer updated to the latest firmware.

To adjust the laser we must first check the current height using the laser shim measuring (.060 cm). Once the laser height is adjusted we can now adjust the laser to be pointing straight. The final step is to check the value of the laser which should read 1023.

1. Laser height

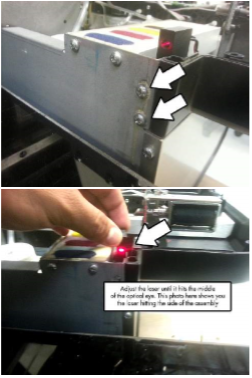

Turn your laser on (laser on under technical menu). See photo 2.7.1

Hit the table down option under the technical menu as this will move your table all the way down, then hit table up this will raise your table to the current laser height. Use your shim and decide if the laser needs to be adjusted. If the shim is loose, the laser has to go up, if the shim does not fit between the carriage and the table then the laser has to go down. See Photo 2.7.2

The laser is held by 2 Phillip screws. Remove the screws to release the laser assembly. The laser bracket will have some glue on it, remove the glue before putting the bracket back. Removing these two screws will also allow you to position the laser up and down. Move your laser up or down depending on how to shim fits. Repeat the step above to check your laser height again. Once the height of the laser is set we can move on to the next step. See photo 2.7.3

We will be using a Gauge block that has a line going down the side. You can use any tool as long as it has a straight line reference. We want the laser to be pointing perfectly straight.We drew a line on the block to use as a guide point. I will check the laser at the far left making sure its leveled to my guide point, and move the block all the way across too see where the laser ends up at. The laser should be in the exact position. The image below shows you it's not straight on the left the laser is directly on my guideline and on the right the laser is above my guideline meaning the laser is slightly pointed up. See photo 2.7.4

Use the last screw to adjust the laser point. The last screws will allow you to adjust in an up and down motion of the laser once it's locked in place. The lasers position should be the same on the left and on the right. See photo 2.7.5

Once your laser is pointing straight we can move on to the next step.

Laser Value 1032

When the laser is hitting the optical eye perfectly the laser value should read 1032.

To check the laser value go to the technical menu under Motion Control. You will see the option to "Read Laser". Hit enter and it will read the current value. If the laser is not hitting the optical eye correctly you will end up with a different value or the numbers will be jumping up and down. The correct value is 1023

The right-hand side laser assembly will have two screws holding it in place. Loosen these screws and adjust the assembly accordingly. Once you have a set position check the Laser value to make sure it's at 1023.

Once you have to correct position of the laser hit table down (under technical menu) then hit table up (under technical menu). Press the "HEIGHT" button to make the automatic adjustment, once its done release your carriage and use the laser shim to check the height.

2.8 Lubrication

2.8.1 Linear Guide Rail -Table

Tools needed.

o Synthetic Oil (P/N-150646-001)

1. lubrication of the linear guide rail for the table is needed for every 100 kilometers (62 miles) of travel. This is equivalent to about 80,000 print cycles for the table. If the unit experiences this number of print cycles or has been operating in a severe environment, the table linear guide rail may be lubricated with synthetic oil applied to the rail side surface.

2. Use a synthetic Oil/lubricant to lubricate the rail guides. Place a couple drop of lubricant to the left and right-hand side of the linear table rail. See photo 2.8.1.

Anajet