Charging or Filling your Melco G2 with Ink

customer

Before your initial power up, you will need to charge the Ink Delivery System.

There are two methods for charging the ink through the lines of your printer. The first uses the power clean function of the printer. The second method is a manual method using a syringe.

Charging the System Using Power Clean Cycles

With the white inks shaken and all eight ink cartridges in the bays, power clean can be performed to move the ink into the lines. You will want to perform the power cleans until the ink is all the way through the print head, and ink is moving into the waste ink tank. It may take two or three cycles.

See the Power Clean section for more instructions related to this function.

Charging the System Manually

With the white inks shaken and all eight ink cartridges in the bays, power clean can be performed to move the ink into the lines. You will want to perform the power cleans until the ink is all the way through the print head, and ink is moving into the waste ink tank. It may take two or three cycles.

See the Power Clean section for more instructions related to this function.

Tools Required

- Phillips Screw Driver

- Ink Syringe

- Paper Towels

- Release the Printhead Carriage

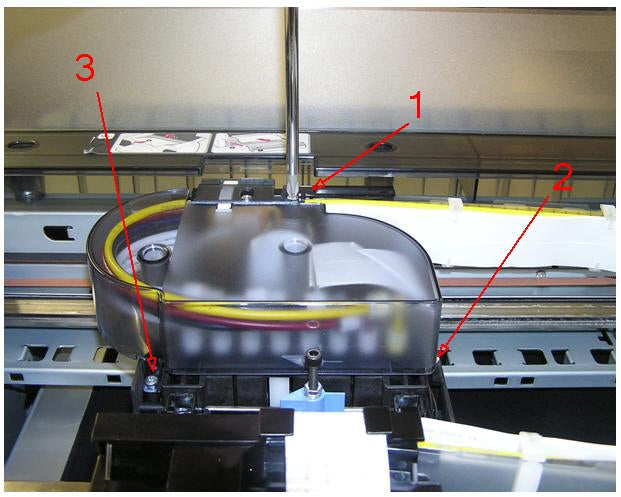

- Remove the (3) Print Head Carriage Cover mounting screws

- Remove the Print Head Carriage Cover to access the ink line fittings.

- Before disconnecting the ink lines, the blue ink delivery system levers will need to be moved into the up position. This closes the lines in the system and prevents any fluid from flowing back into the cartridges when the line is removed from the damper.

- Disconnect the ink line from the damper connection by unthreading the white compression nut from the damper fitting. The white compression nut may need to be moved down the line to allow access for the syringe. The black o-ring can stay.

- Attach the syringe to the ink line and pull on the plunger a very tiny amount. The goal is to create the slightest amount of suction which will cause the ink/fluid will flow forward through the system when the blue ink levers are moved to the lower position.

- Move the blue ink system levels to the down position. This will open the lines in the system and allow ink/fluid to flow through the system and into the syringe.

- Draw the ink/fluid into the line. Be careful not to apply too much force or try to pull too much ink all at once. Keep the pressure even and steady until you see the line fill with ink.

- Before removing the syringe, raise the blue ink system levers to close the lines in the system again. This will prevent any fluid from flowing back into the cartridges when the syringe is removed from the line.

- If multiple pulls on the syringe are necessary, you will need to repeat steps 4 through 9. Remember that whenever the end of the ink line is exposed, the ink system levers need to be in the up position to prevent ink/fluid from flowing back into the cartridges or forward into the printer.

- Reconnect the ink line to the damper fitting by attaching the white compression nut to the fitting and securely tightening to be sure no air will be allowed into the Ink Delivery System.

- Repeat the process for all remaining ink lines.

- Replace the Print Head Carriage Cover with the same (3) cover mounting screws.

- Return the Print Head Carriage to the parked position and move the ink system levers to the down position to open the lines in the system and allow ink to flow for printing.